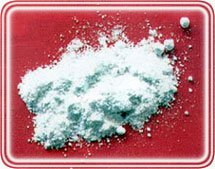

Caustic magnesite

Technotrade Company supplies a completely new and practical material. -

Caustic magnesite, at the best prices!

Caustic magnesite is an air binder obtained by roasting natural magnesite followed by grinding the product into a fine powder.

Caustic magnesite is an air binder obtained by roasting natural magnesite followed by grinding the product into a fine powder.

In the firing process, the main component of magnesite is magnesium carbonate (MgCO3), decomposes into magnesium oxide (MgO) and carbon dioxide (CO2). Firing is carried out at a temperature above the decomposition temperature of magnesite (550 ° C), but below its sintering temperature. Typically, the firing temperature is 800-850 ° C. The caustic magnesite thus obtained is subsequently ground in ball mills. And as a result, caustic powder is formed, which, according to GOST, is divided into three classes depending on its chemical composition. The powder of the first class is intended for the chemical industry, and the second and third - is used in construction, as a binder.

It should be noted that caustic magnesite is not shut off with water (since in this case it has low strength), but with a solution of magnesium chloride, magnesium sulphate or some other salts. Caustic magnesite shuttered with a solution of salts is called magnesian cement or Sorel cement. Which is used for the production of xylolite and fibrolite, as well as for the manufacture of plaster solutions, thermal insulation materials, artificial marble, artificial millstones and some other products.

The strength of caustic magnesite solutions reaches 1000 kgf / cm2. The strength of magnesian concrete during 1 day reaches 30-50%, and in the period of 7 days - 60-90% of the maximum possible. Magnesia binder has a very high adhesion

Caustic magnesite is a modern, durable and reliable binder!

|

MgO (min) – 88% CaO (max) - 4,5% SiO2 (max) – 6% LOI (ППП) – 5% Activity – 62 – 64 |

|

Packing: big bag

Storage: Store in a dry, laying, ventilated room.

Terms of delivery: CFR Odessa Commercial Sea Port

Minimum lot of 26 tons